Aerogels for Window Insulation

Description:

Building Material Category: Window Insulation

Building Component Type: Fenestration-Glass, Fenestration-Frames and Wall

Alternative for Conventional Building Material: Traditional insulation materials like fiberglass or foam.

Introduction: Aerogels are an advanced class of materials known for their exceptional insulating properties and lightweight nature. When used in window insulation, aerogels offer several unique advantages over traditional insulation materials. Aerogel is a solid material based on silicon with extremely low density. They are created by removing the liquid component from a gel, leaving behind a highly porous solid with a structure that is 90-99% air. Advanced aerogels used in window insulation outperform conventional materials like fiberglass or foam due to their superior thermal insulation properties. Made from sustainable materials, aerogels contribute to energy efficiency and environmental sustainability in building applications.

Composition: Generally made from silica or polymer aerogels, which are highly porous and low-density materials.

Applicability in Climatic Zone: Suitable for all climatic zones in India, especially effective in extreme climates due to its superior thermal performance.

Use: It is used primarily for window insulation, filling gaps in building envelopes, and as thermal barriers in walls and roofs.

Thermal Performance: It offers excellent thermal resistance, effectively reducing heat transfer across building surfaces. The thermal performance of aerogels in insulation depends primarily on their material composition, pore structure, density, surface area, moisture content, and temperature.

Thermal Conductivity:Typically ranges from 0.012 to 0.025 W/mK, indicating very low thermal conductivity.

Thermal Transmittance: Ranges from 0.004 to 0.009 W/m²K, reflecting its ability to achieve low U-values.

Reduction in CO2 Emissions: Aerogel glazing significantly contributes to CO2 emissions reduction by enhancing thermal insulation and lowering the energy required for building heating and cooling. While the exact percentage of emissions reduction can vary, aerogel glazing can lead to reductions of 20% to 40% in operational CO2 emissions due to decreased energy consumption. The long-term benefits and energy savings make aerogel glazing a valuable option for sustainable building design.

Salient Features:

- Exceptional Thermal Insulation: Aerogels possess extremely low thermal conductivity, which is much lower than traditional insulation materials like fiberglass or foam. This property allows aerogels to provide superior insulation, minimizing heat transfer through windows and reducing heating or cooling energy requirements in buildings.

- Low U-value: The U-value of aerogels for window insulation is low, indicating their ability to effectively prevent thermal bridging and heat loss, thereby improving the overall energy efficiency of buildings.

- Thin Profile: Aerogels are exceptionally thin compared to traditional insulation materials while still offering high thermal resistance. This characteristic is advantageous for retrofitting existing windows without significantly altering their appearance or functionality.

- Lightweight: Being lightweight, aerogels are easy to handle and install, reducing labor costs and logistical challenges during construction or renovation projects.

- Moisture Resistance: Aerogels are inherently hydrophobic, meaning they repel moisture. This property helps maintain their thermal performance over time by preventing degradation or loss of insulation effectiveness due to moisture absorption.

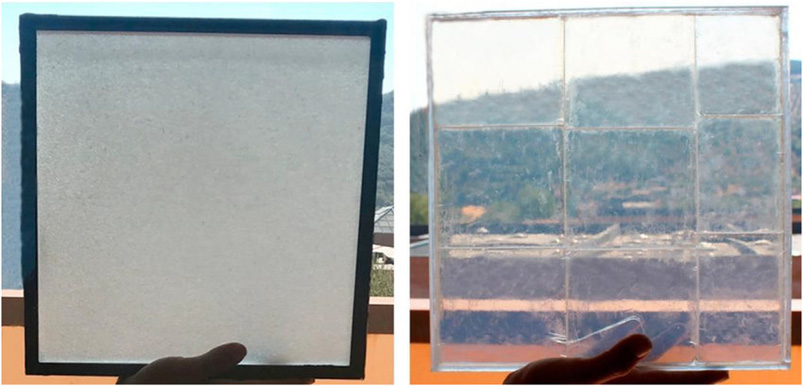

- Transparency: Some aerogel formulations are translucent or transparent, allowing natural light to pass through while still providing insulation benefits. This feature enhances daylighting in buildings, reducing reliance on artificial lighting and further improving energy efficiency.

- Durability: Aerogels are durable materials with a long lifespan. They are resistant to compression, settling, and degradation, ensuring sustained thermal performance over many years.

- Environmentally Friendly: Aerogels are often made from silica or other sustainable materials. Their energy-saving properties contribute to reducing carbon footprints associated with building operations.

- Versatility: Besides window insulation, aerogels can be used in various building applications such as walls, roofs, and HVAC systems, further enhancing overall building energy efficiency.

Indian Codes for Aerogels in Window Insulation:

As of now, there are no specific Indian codes exclusively dedicated to aerogels for window insulation. However, related standards and guidelines cover aspects of insulation materials and building performance:

- IS 1443:1977 – Methods of Test for Insulating Materials: Provides testing methods for insulating materials, which can be relevant for evaluating aerogels.

- IS 3362:1985 – Specification for Thermal Insulation for Building Applications: Covers thermal insulation materials and their performance, which can be applied to new materials like aerogels.

- National Building Code (NBC) of India: General guidelines for building construction, including insulation practices, which may be adapted for aerogel applications.

International Codes for Aerogels in Window Insulation:

International standards and guidelines offer more specific protocols for aerogels and their applications:

- ASTM C 518 - Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus: Provides testing methods for the thermal conductivity of insulating materials, including aerogels.

- ISO 8301 - Thermal Insulation - Determination of Steady-State Thermal Resistance and Related Properties: Specifies methods for measuring the thermal resistance of insulation materials, applicable to aerogels.

- EN 13162 - Thermal Insulating Products for Building Applications - Factory Made Mineral Wool Products: Though focused on mineral wool, this standard offers guidelines for insulation that can be informative for aerogel applications.

- ASTM C 1623 - Standard Specification for Aerogel Insulation: Specifically addresses aerogel insulation products, detailing their properties and performance requirements.

- ISO 12667 - Thermal Insulation - Determination of Thermal Conductivity by Means of the Guarded Hot Plate Apparatus: Provides methods for measuring the thermal conductivity of insulation materials, including aerogels.

While specific Indian codes for aerogels in window insulation are not yet established, related standards and guidelines provide a basis for evaluating and applying new materials. International codes offer more detailed protocols for aerogels, covering their performance and testing methods. Keeping up with developments in both national and international standards is crucial for effectively using aerogels in insulation applications.

Manufacturers:

As of now, aerogel glazing is a specialized technology and not widely adopted in India compared to other types of insulation. However, there are several companies and research institutions involved in advanced materials and building technologies that may offer aerogel or similar high-performance insulation solutions. Here’s a list of some manufacturers and suppliers in India that could be involved in or exploring aerogel glazing:

- Aerogel Technologies: Specializes in advanced aerogel products and may offer aerogel-based solutions including glazing applications.

Website: Aerogel Technologies - Thermal Ceramics (a division of Morgan Advanced Materials): Provides advanced insulation materials and might offer products that include aerogel technology.

Website: Morgan Advanced Materials - BASF India: A major player in construction materials and chemicals, BASF India is involved in advanced building technologies and might offer or be developing aerogel solutions.

Website: BASF India - Indian Institute of Technology, Madras: IIT Madras is involved in research related to advanced materials, including aerogels.

Website: IIT Madras

While aerogel glazing is still emerging in India, several companies and research institutions are involved in advanced materials and might be exploring or offering aerogel-based solutions. For the most current information and potential suppliers, it's beneficial to reach out directly to these companies or consult with industry experts and research institutions involved in high-performance building materials.

Sources