Vacuum Insulated Panels

Description:

Building Material Category: Insulation Products

Building Component Type: Wall and Roof

Alternative for Conventional Building Material: Traditional insulation materials like fiberglass or foam

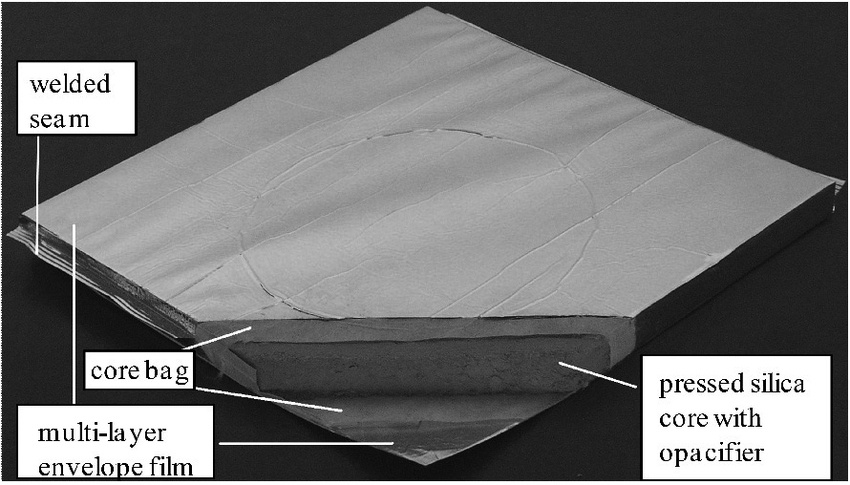

Introduction: VIPs consist of a core material encased in a vacuum-sealed envelope. The vacuum provides excellent insulation by minimizing heat transfer through conduction and convection, leading to extremely low thermal conductivity values. They offer much higher thermal insulation for the same thickness, which is beneficial for applications with space constraints or where high insulation is required without increasing the thickness of walls or floors. VIPs surpass conventional building insulation in thermal performance with much lower conductivity, resulting in superior energy efficiency. They offer thinner profiles, maximizing interior space, and contribute to significant long-term energy savings and sustainability benefits due to their durable, recyclable materials.

Composition: VIPs consists of a thin core of fumed silica or aerogel material enclosed within a vacuum sealed envelope, which minimizes heat transfer through the panel. The core material is made of silica aerogel, microporous silica, or fiberglass. For the envelope, a barrier layer made from aluminum foil or metallized plastic film that maintains the vacuum is developed.

Applicability in Climatic Zone: Suitable for all climatic zones in India, offering effective insulation against both heat and cold.

Use: It is used primarily for insulation in walls and roofs of residential, commercial, and industrial buildings, offering high insulation performance in minimal space.

Thermal Performance: It offers very low U-values, indicating extremely high thermal resistance and minimal heat loss. The thermal transmittance (U-value) of VIPs depends on the quality of vacuum maintained, properties of the core material (such as thermal conductivity), effectiveness of edge sealing to prevent air infiltration, and dimensions of the panel.

Thermal Conductivity: VIPs typically exhibit thermal conductivity values ranging from 0.002 to 0.007 W/mK, depending on the core material used. This is significantly lower compared to conventional insulation materials.

Thermal Transmittance: VIPs provide very low thermal transmittance, depending on the panel thickness. U-values for VIPs are exceptionally low, typically between 0.002 to 0.007 W/m²K, reflecting their outstanding insulation capability.

Reduction in CO2 Emissions: The use of Vacuum Insulated Panels (VIPs) can significantly reduce CO2 emissions through their exceptional thermal performance. VIPs provide thermal conductivity values as low as 0.004 W/(m·K), which is much lower than traditional insulation materials such as fiberglass or foam boards, typically ranging from 0.030 to 0.040 W/(m·K). This high insulation efficiency means that buildings using VIPs require less energy for heating and cooling.

For instance, if a building insulated with conventional materials requires 100 kWh/m²/year of energy for heating, replacing this insulation with VIPs could cut the energy demand by up to 70% due to their superior thermal performance. This reduction in energy consumption translates to a decrease in CO2 emissions. For example, if the average CO2 emissions from electricity production are around 0.5 kg CO2/kWh, reducing energy consumption by 70 kWh/m²/year would result in a CO2 emission reduction of approximately 35 kg CO2/m²/year.

Additionally, VIPs' high efficiency allows for thinner walls, which not only saves on material costs but also contributes to reduced construction footprint. This reduction in material usage further decreases the overall carbon footprint associated with building construction. By adopting VIPs, buildings and products can achieve significant reductions in CO2 emissions, making a substantial impact on environmental sustainability.

Salient Features:

- Exceptional Insulation: VIPs achieve extremely low thermal conductivity, significantly reducing heat transfer through walls or roofs compared to traditional insulation materials.

- Space Efficiency: VIPs provide high insulation value in a very thin profile, allowing for maximum interior space utilization in buildings.

- Minimal Thickness: Despite their thinness (typically around 20 to 50 mm), VIPs offer superior thermal resistance, making them ideal for applications where space is limited but high insulation performance is critical.

- Energy Savings: By minimizing heat loss or gain, VIPs contribute to substantial energy savings in heating and cooling systems, leading to lower operational costs over the building's lifespan.

- Long-Term Performance: VIPs maintain their high insulation effectiveness over time due to the vacuum-sealed environment, which prevents convective heat transfer and degradation of insulation properties.

- Durability: They are durable and resistant to moisture ingress, ensuring prolonged performance without compromising insulation efficiency.

- Environmental Benefits: VIPs are made from recyclable materials and contribute to reducing greenhouse gas emissions associated with building energy use.

- Versatility: Suitable for various building applications including walls, roofs, and floors, VIPs offer flexibility in design and construction while enhancing overall building energy efficiency.

Indian Codes:

As of now, there are no specific Indian codes exclusively dedicated to Vacuum Insulated Panels. However, general guidelines and standards related to building insulation may apply. Relevant Indian standards include:

- IS 3346: Code of Practice for Thermal Insulation of Buildings-This standard covers the general principles of thermal insulation in buildings, although it does not specifically address VIPs.

- IS 1442: Method of Testing for Thermal Insulation-This standard includes methods for evaluating the thermal performance of insulation materials, which can be relevant for testing VIPs.

International Codes:

VIPs are referenced and tested according to several international standards, including:

- ISO 9465: Vacuum Insulated Panels (VIPs) – Determination of Thermal Conductivity-This standard provides the method for measuring the thermal conductivity of VIPs, crucial for assessing their performance.

- ASTM C1307: Standard Test Method for Thermal Performance of Vacuum Insulated Panels-This test method is used to evaluate the thermal performance of VIPs, providing guidelines for determining their effectiveness.

- EN 16012: Thermal Insulating Products for Buildings – Vacuum Insulating Panels (VIPs)-This European standard specifies the requirements and test methods for VIPs used in building applications, including their thermal performance and durability.

- ISO 8497: Determination of the Thermal Resistance of Vacuum Insulated Panels - This standard outlines the procedures for testing the thermal resistance of VIPs.

These international codes ensure that VIPs meet rigorous performance criteria and maintain their insulating properties over time. For specific applications and regions, it is advisable to consult these standards and verify compliance with local regulations and requirements.

Manufacturers:

There are a few companies involved in the production and supply of VIPs or similar advanced insulation materials. Some notable manufacturers and suppliers include:

- Wedge India: https://www.wedge-india.com/vacuum-insulated-panel

- KnaufInsulation: https://www.knaufinsulation.com/

Sources: