Insulated Concrete Forms

Description:

Building Material Category: Insulation Products

Building Component Type: Wall

Alternative for Conventional Building Material: Traditional concrete blocks

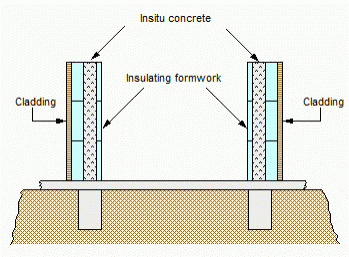

Introduction: Insulated concrete forms are a building system that combines rigid thermal insulation with concrete in a modular form. The forms are stacked to create walls and then filled with concrete, providing both structural strength and high thermal insulation. Unlike conventional materials, ICFs provide integrated insulation and structure, eliminating the need for separate insulation layers and improving energy efficiency.

Composition: Insulation of ICF is typically made of two layers of expanded polystyrene (EPS) or extruded polystyrene (XPS) foam, which provides high thermal insulation. Reinforced concrete is poured into the cavity between the insulation panels, providing structural integrity and load-bearing capacity.

Applicability in Climatic Zone: Suitable for all climatic zones in India, offering effective insulation against both heat and cold.

Use: It is used primarily for constructing walls in residential, commercial, and industrial buildings requiring high thermal performance. It serves as formwork for pouring concrete and remains in place as insulation after the concrete sets.

Thermal Performance: It offers excellent thermal insulation properties, significantly reducing heat transfer through walls. The thermal transmittance (U-value) of ICFs depends on the quality and thickness of the insulation material (typically EPS foam), the density of the foam, the thermal conductivity of the concrete core, installation practices to minimize thermal bridging, and environmental conditions.

Thermal Conductivity: Thermal conductivity of EPS and XPS typically ranges from 0.030 to 0.035 W/mK, indicating low thermal conductivity.

Thermal Transmittance: U values of ICF walls range from 0.15 to 0.3 W/m²K, depending on the thickness of the insulation and concrete.

Reduction in CO2 Emissions: The use of Insulated Concrete Forms (ICFs) significantly reduces CO2 emissions through enhanced energy efficiency and reduced embodied carbon. ICFs improve thermal insulation, cutting annual energy consumption by 30–50%, which translates into a proportional decrease in CO2 emissions from energy production. Additionally, ICFs streamline construction by combining insulation and structural components, resulting in a 5-15% reduction in embodied carbon compared to traditional building methods. This dual benefit of lower operational and embodied carbon makes ICFs a key component in sustainable building practices, contributing to significant overall CO2 emissions reduction.

Salient Features:

- Superior Insulation: It incorporates EPS foam, providing continuous insulation across walls, minimizing thermal bridging, and enhancing energy efficiency.

- High Thermal Resistance: It achieves low U-values, significantly reducing heating and cooling energy consumption compared to traditional materials.

- Energy Savings: It reduces operational costs by maintaining consistent indoor temperatures throughout the year, reducing reliance on mechanical heating and cooling systems.

- Durability: Reinforced concrete core provides structural strength and durability against fire, mold, pests, and impact, ensuring long-lasting building performance.

- Sound Insulation: It offers effective soundproofing, creating quieter indoor environments by attenuating external noise transmission.

- Construction Efficiency: It facilitates faster construction with fewer phases, simplifying assembly and reducing labor requirements.

- Environmental Sustainability: It is made from recyclable materials, promotes sustainable building practices, reduces greenhouse gas emissions, and minimizes construction waste.

- Design Versatility: It is compatible with various architectural designs and construction methods, offering flexibility in building aesthetics and functional requirements.

Indian Codes:

Currently, there is no specific Indian code that directly addresses ICFs; however, general concrete and insulation standards apply.

- IS 456:2000: Code of Practice for Plain and Reinforced Concrete-This code provides general guidelines for the design and construction of concrete structures, including those using ICFs. It covers aspects like mix proportions, structural requirements, and construction practices.

- IS 3370 (Part 2): 1965—Code of Practice for Concrete Structures for the Storage of Liquids Though not specific to ICFs, this code addresses concrete construction practices relevant to the durability and performance of concrete, which are applicable to ICF systems.

- IS 1905:1987—Code of Practice for Structural Use of Unreinforced Masonry—This code includes guidelines for masonry structures, which can be useful when integrating ICFs with masonry components.

International Codes:

- ASTM C 90: Standard Specification for Loadbearing Concrete Masonry Units-This specification covers the requirements for concrete masonry units, including those used in ICF systems, ensuring they meet structural and durability standards.

- ICC 500: Standard for the Design and Construction of Storm Shelters-This standard includes requirements for the construction of storm shelters, which often utilize ICFs for their robustness and insulation properties.

- ASTM E 84: Standard Test Method for Surface Burning Characteristics of Building Materials-This test method evaluates the fire resistance of building materials, including ICF systems, which is crucial for assessing their performance in fire conditions.

- ISO 140-3: Acoustics—Measurement of Sound Insulation in Buildings and of Building Elements-This standard provides methods for measuring the sound insulation of building elements, including ICF systems, important for assessing their acoustic performance.

Sources