Mud Kothi

This project aimed to create a house that harmonizes with its surroundings by using local natural materials, minimizing the reliance on high embodied energy resources. Located near the Aravalli Mountains, the farmhouse will seamlessly integrate with the area's topography. The use of materials like mud, stone, baghra (lime waste from kilns), lime, surkhi, and thatch not only connects the home aesthetically with nature but also ensures functionality. While these materials have traditionally been employed in rustic designs, this project reimagines them for contemporary spaces, offering a sustainable and innovative approach to shelter that meets modern needs with a low carbon footprint.

| Location | Alwar, Rajasthan |

| Address | Baadi, Near Dhai pedi, Umren, Old Jaipur Road, Alwar |

| Building Typology | Residential |

| Climate Zone | Composite |

| Date of Completion | 2021 |

| Site Area | 2.5 Acre |

| Build-up Area | 2,000 sq. ft. |

| Number of Floors | Ground only |

| Project Coordinator | Aashi Agarwal |

| Principal Architect | Shipra Singhania Sanghi, Sketch Design Studio |

| Landscape Architect | Edible Routes |

| Structural Consultant | Ar. Mangesh Jhadhav - Rammed Earth Consultant |

| Electrical Consultant | Mr. Trilok Chand Chawla |

| Project Management Consultant | Mr. Sundari and Mr. Kaluram |

Building Form and Fenestration

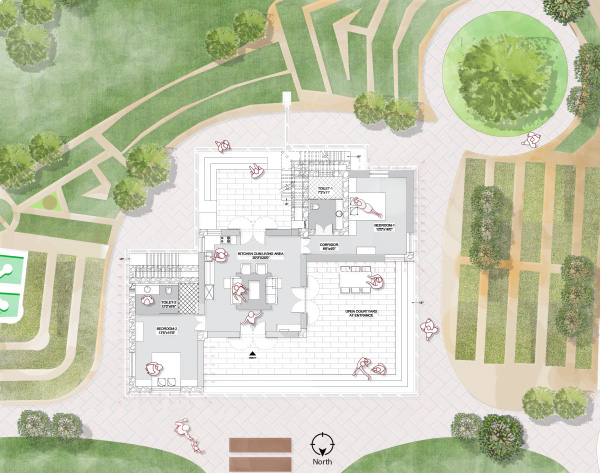

Orientation of building – The longer axis of the building is oriented in east-west directions, with more facade area oriented towards north and south. The rooms are not arranged in a line, but staggered to each other. It helps in mutual shading in the north and south side facades. The main entrance is towards the north. Two bedrooms on either side of the central living room facing north east and north-west direction. All the service areas create a thermal barrier from the south side for the bedroom and living spaces. Bathrooms, stairs and the kitchenette are located along the south and southwest facing of the building. It reduces the heat gain of the main habitable spaces.

Building form: Higher roof in the central space, which will give enough room for hot air to rise above and be segregated from the living space. Fixed windows for increasing the heat gain during the winters. It also maximises the views, connecting the internal and external spaces.

Daylighting: Large openings are provided in all rooms to reduce dependence on artificial lighting during the daytime.

Building Envelope and Construction Materials

- Envelope & Fenestration: Using materials with higher thermal mass in the walls to reduce the heat gain of the structure. The wall thickness is also high, ranging from 1.5 ft (regular walls) to 4.5 ft (south side under the stair walls). Higher wall thickness increases the time for heat transfer. Use of thatch roof made of local grass, with high insulation decreases the heat gain during the daytime. As a result, the interiors remain cooler than a conventional building, reducing the energy needs for cooling. Materials & Construction: Low carbon, energy efficient materials were used in the construction of the buildings. Being local materials, they are also climate responsive and lead to energy efficiency in cooling usage in the building.

- Earthbag walls using the local soil and lime, filled in bags, and compacted using a rammer to make a masonry unit. It has a high thermal mass and wall thickness.

- Rammed earth walls which highlight the aesthetics of raw earth and provide a monolithic strong wall. Soil, lime, and aggregates are rammed together layer by layer within shutters on both sides. These walls are cast in the exact position of the wall as monolith units. Earthbag and Rammed Earth walls are using the method of dry mixes of soil, which requires less water in construction compared to other traditional methods of building with mud. Techniques using mechanical compression gives walls with a better strength than other traditional methods like adobe. Having stronger walls helps in optimising the thickness of the walls, thereby providing better space utilisation and thermal mass.

- Stones are one of the widely available local materials in Rajasthan. Use of stones for building walls for spaces were bathrooms or in the direction of prominent rains helped in keeping the mud walls unaffected by water. The mortar uses ‘Baghra’ instead of lime – which is the waste from manufacturing of lime. Bajri (River sand) is widely used with Bagra traditionally for building walls and for plasters. In this project, all the stones used for building walls and foundation are reclaimed from old, dilapidated buildings. No stone was brought from a quarry. Excessive mining for stones has adverse effects on ecology and its use should be limited in construction.

HVAC Air Conditioning

Ceiling and wall fans are introduced, to improve comfort by air movement and circulation wherever required. Further Split Acs are provided in each room, to be used on requirement basis.

Artificial Lighting and Controls

Ceiling as well as wall lights are provided for optimal comfort using LEDs

- Sketch Design Studio. (n.d.). Mud House in Alwar. ArchDaily. Retrieved December 9, 2024, from https://www.archdaily.com/989711/mud-house-sketch-design-studio